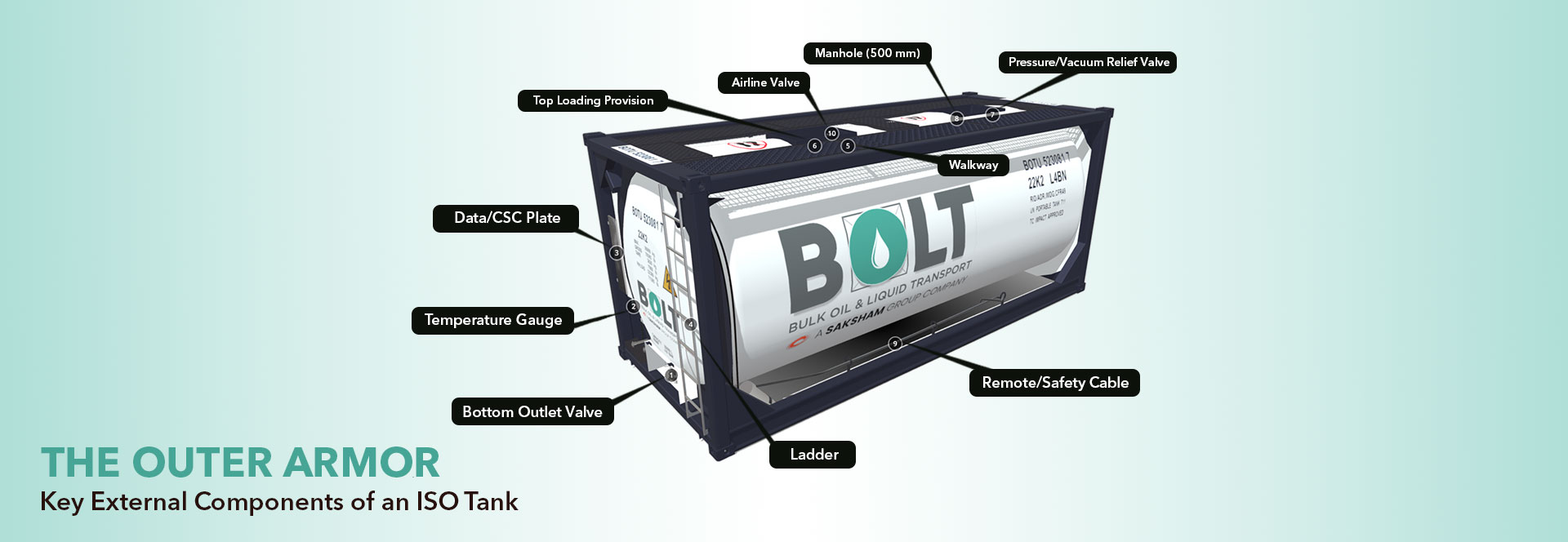

ISO Tanks: A Deep Dive into Essential External Components

In the bustling world of global trade, ISO tanks are the unsung heroes, transporting a vast array of liquids and even some solids across continents. While they might appear simple on the outside, these containers rely on a network of crucial external components to guarantee safe and efficient operation. Let’s take a closer look at these key components and understand their individual functionalities.

-

Top Loading Valve

At the heart of every ISO tank’s top lies the top loading provision. This specially designated area ensures the safe and efficient filling of the tank with its cargo. Depending on what’s being transported, this provision includes hatches, valves, and connections tailored to facilitate the loading process seamlessly.

-

Manhole (500 mm)

Ever wondered how maintenance crews get inside ISO tanks? Enter the manhole, typically 500 millimeters in diameter. Positioned on the top, this essential access point allows personnel to enter the tank for cleaning, inspection, and maintenance. And don’t worry—when not in use, it’s securely closed to keep the tank’s contents safe and sound.

-

Pressure/Vacuum Relief Valve (P/V Valve)

Meet the ISO tank’s safety guardian: the Pressure/Vacuum Relief Valve, or P/V Valve for short. This self-activating valve automatically vents excess pressure or vacuum that may build up inside the tank during filling, emptying, or due to temperature changes. It’s the unsung hero that prevents potential ruptures, safeguarding the tank, its cargo, and everyone around it.

-

Airline Valve

The airline valve controls the flow within ISO tanks. During unloading, it creates a vacuum by drawing air out of the tank. This pressure difference pulls the product out. The valve can then stay open to allow continued flow by gravity or pumping pressure. Additionally, the valve helps maintain dry air or nitrogen pressure inside the tank, preventing contamination by keeping unwanted air out.

-

Temperature Gauge

Think of the temperature gauge as the ISO tank’s built-in thermometer. This vital instrument constantly monitors the internal temperature of the cargo. From bi-metallic to digital versions, these gauges provide crucial information to ensure the product stays in perfect condition. Advanced gauges even use sophisticated sensors like RTDs or thermocouples for highly accurate readings, with some integrated with alarm systems to alert if temperatures deviate from safe limits.

-

Pressure Gauge

The pressure gauge is crucial for safe handling and preventing leaks in ISO tanks. It continuously monitors the internal pressure within the tank, ensuring it stays within safe limits. Often linked to the P/V Valve, in this case, the pressure gauge triggers it to open when pressure exceeds safe levels, releasing excess pressure and preventing ruptures. Constructed from materials compatible with the specific cargo, these gauges ensure durability and accurate readings.

-

Bottom Outlet Valve

Located at the tank’s base, the Bottom Outlet Valve controls the flow of product during loading and unloading in ISO tanks. Engineered to handle the weight and pressure of the cargo, Bottom Outlet Valves ensure a leak-proof seal. These valves come in various designs, such as high lift or clean flow, depending on the specific type of cargo being transported.

-

Remote/Safety Cable

This crucial cable acts as an extension of the Bottom Outlet Valve, allowing operators to safely close the valve from a distance in case of emergencies. This minimizes exposure to hazardous fumes or pressurized contents that may occur during a leak situation. Some safety cables are equipped with a fusible link that automatically shuts the BOV in case of fire, preventing spills or leaks. Together, the BOV and remote/safety cable ensure safe and controlled unloading.

-

Data/CSC Plate

The Data/CSC Plate is the ISO tank’s identification card, displaying vital information such as:

- Tank owner details

- Tank identification number

- Manufacturing date

- Maximum Allowable Working Pressure

- Tank material

- Maximum gross and tare weight

- Test and inspection dates

This plate ensures compliance with international regulations and safe handling practices.

-

Document Box

The document box acts as a portable filing cabinet for ISO tanks. It houses essential documents related to the tank and its cargo, including:

- Test certificates

- Cleaning certificates

- Cargo information and Safety Data Sheets (SDS)

- Bill of Lading

- Dangerous Goods Declaration

The document box keeps these critical documents organized and accessible.

Understanding the external components of ISO tanks highlights the intricate engineering and safety measures that go into making these containers indispensable for global trade. From ensuring safe loading and unloading processes to maintaining cargo integrity and compliance with international standards, each component plays a vital role. As the backbone of efficient and secure transport, ISO tanks and their meticulously designed features are crucial for industries worldwide. Whether you’re in logistics, manufacturing, or any field that relies on transporting liquids and solids, appreciating the sophistication of ISO tanks can enhance your operations and ensure the safe delivery of your valuable cargo.

Blog By: